Screw Conveyor

Screw Conveyor Manufacturer & Exporter in India

Trivella is a company that specializes in the manufacture of screw conveyors. Screw conveyors are used in a variety of industries to transport materials such as powders, granules, and flakes. They consist of a helical screw blade that rotates within a tube, moving the material along the length of the conveyor.

Trivella screw conveyors are designed to be reliable and efficient, with low maintenance requirements. They can be customized to meet the specific needs of each application, with a range of materials and configurations available.

In addition to screw conveyors, Trivella also offers a range of other material handling equipment, including belt conveyors, bucket elevators, and pneumatic conveyors. With a focus on quality and customer service, Trivella has become a trusted name in the industry.

What Is Screw Conveyors ?

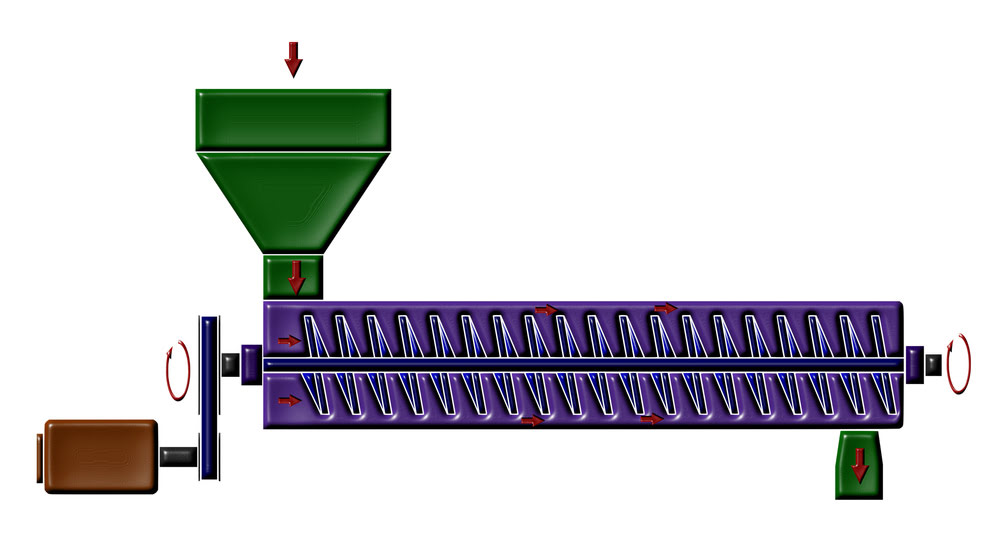

Screw conveyors are a type of mechanical conveyor that are commonly used to transport bulk materials such as powders, granules, and flakes. They consist of a helical screw blade that rotates within a tube, moving the material along the length of the conveyor. The screw is driven by a motor, which can be located either at one end of the conveyor or in the center.

Screw conveyors are known for their reliability and versatility, as they can handle a wide range of materials and can be customized to fit the specific needs of each application. They are also easy to maintain and operate, making them a popular choice in many industries.

Components of Screw Conveyors

The main components of a screw conveyor include:

Screw Conveyor Features

Screw conveyors offer several features that make them a popular choice for material handling in a variety of industries. Some of these features include:

Overall, the features of screw conveyors make them a reliable, efficient, and versatile choice for material handling in many industries.

Screw Conveyors Application

Screw conveyors are used in a wide range of applications across various industries. Some common applications of screw conveyors include:

These are just a few examples of the many applications of screw conveyors. Their versatility and reliability make them a popular choice for material handling in a wide range of industries.